Hi Everyone,

I’d like to share with you a little project I’ve been working on in my spare time. It’s an open-source, Daisy based Eurorack module in only 4hp. It’s called the kxmx “bluemchen” (little flower in German) and looks like this:

It’s basically a Patch with fewer controls. Heres what it does have:

1 Rotary encoder with switch

1 64x32 OLED display

2 Potentiometers

1 MIDI in

2 CV in

2 Audio in

2 Audio out

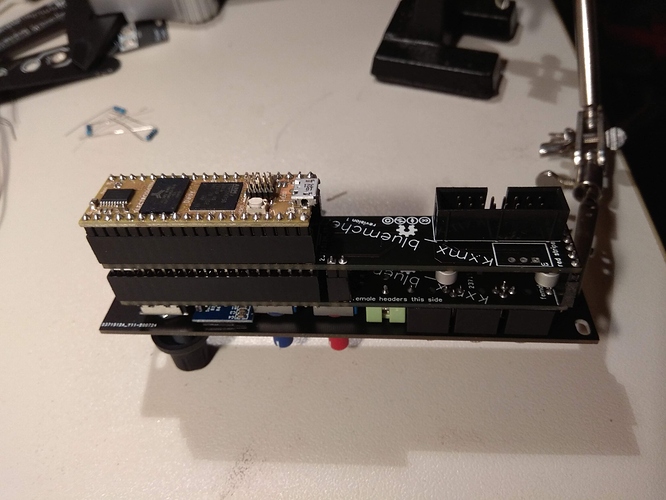

I needed two PCBs to accommodate the components. I ended using 20 pin stacking headers to get some of the Daisy signals from front to back. I used 0603 SMT parts and it’s hand solderable. Here’s what it looks like from the side/back:

I’ve tested most of it from a hardware design perspective. The encoder, CV, Audio, MIDI all work in the prototype. I’ve successfully flashed some of the example patch firmware.

I haven’t tried getting the OLED going, as the patch version is SPI, and this little one only comes with I2C signals (I’m not entirely convinced a screen is a good idea anyway).

The prototype is prone to the same digital noise problems a few people here have mentioned. I’ve since the revised the power supply to more reflect the design of the Patch, but it’s not yet been tested.

On the software side of things, I’ve done nothing but test basic functionality. I’ll try and address this when the new power design has been prototyped and tested.

As mentioned this is an open source design. Here’s the back board:

…and the front board:

…and a front panel:

I hand picked the components from LCSC and prioritized parts that have PCBA support and high stock counts where possible. With the exception of the Daisy, OLED, and the Jacks, you should be able to order the entire BOM in one go.

I’ve been sitting on this prototype for a while, unable to find the time/motivation to move things forward. I figure if I just put it out there, and there is interest, perhaps it will get things going again. I’d appreciate any kind of feedback!