I came to this post looking for a solution to noise on a breadboard while learning Daisy.

The noise doesn’t occur with the Daisy powered by usb, but there was awful noise running from the power from the OMSynth.

If you are like me, and just looking for a way to eliminate the noise while breaboarding and learning–a simple solution was found using 3 100uf electrolytic capacitors. (I used 100uf Nichicon PETs, not sure if these specifically helped or not)

| Capacitor |

Negative Terminal |

Positive Terminal |

| Cap 1 |

Ground Rail |

Power Rail |

| Cap 2 |

DGND |

Vin |

| Cap 3 |

AGND |

AudioOUT2 |

(In the recently curated oscillator and drum examples, AudioOut2 is tied to ground.

If you want to use both (AUDIo_Out 1 & 2), replace the 100uF electrolytic with a 100nF or such-like, preferably film…)

Connecting the capacitors:

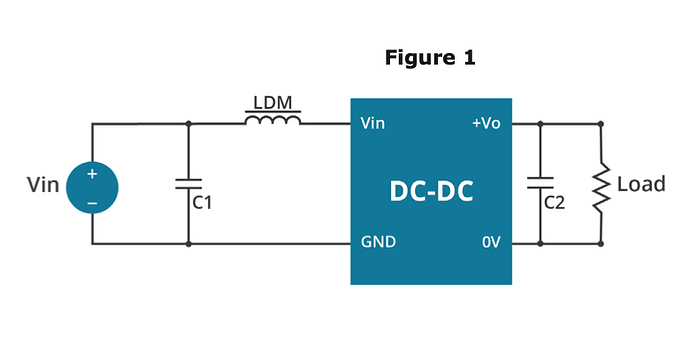

Capacitor 1: Connect the negative terminal to the ground rail and the positive terminal to the power rail. This configuration helps stabilize the power supply and reduce noise by providing a low-impedance path for high-frequency noise to bypass the sensitive circuitry. The capacitor acts as a reservoir, smoothing out voltage fluctuations and reducing the impact of noise on the system.

Capacitor 2: Connect the negative terminal to DGND (Digital Ground) and the positive terminal to Vin (Voltage input). This configuration specifically targets noise in the digital circuitry. Digital components, such as microcontrollers or digital logic, can generate fast switching currents that introduce noise. By connecting a capacitor between the digital ground and the voltage input, high-frequency noise is filtered out, ensuring a clean power supply for the digital components.

Capacitor 3: Connect the negative terminal to AGND (Analog Ground) and the positive terminal to AudioOUT2. In some of the DaisyExamples, such as the new oscillator and drum demos, AudioOut2 is tied to ground. This configuration focuses on noise reduction in the analog audio output circuitry. By connecting a capacitor between the analog ground and the audio output, any noise present in the audio signal is attenuated, resulting in cleaner audio output.

I did this for just running a modified version of the oscillator example–so nothing super fancy–we’ll see if this is still effective with reverbs, delays, etc. However, there is no longer any blatant horrid audible noise at present, but still a slight hum, like a mosquito is in the room (we will squash this before the end)…

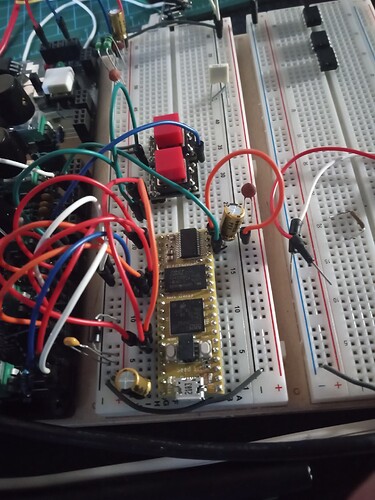

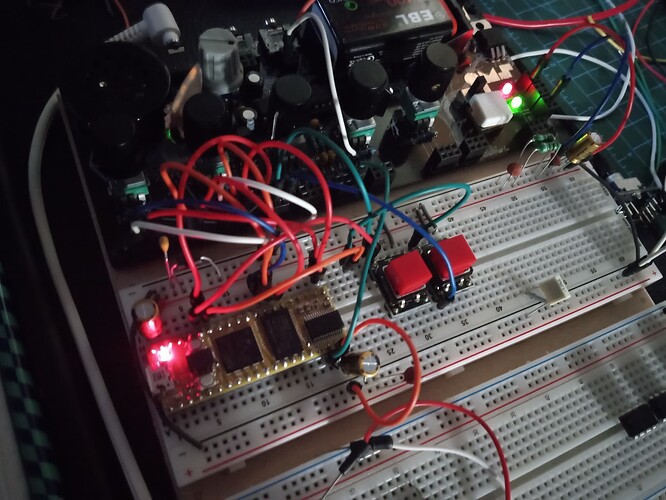

You may notice from the picture there are 100nf/0.1uf decoupling capacitors everywhere there is a spout from ground or power to the Daisy. There are also some near the power entry point (probably overkill, but this is a noise-elimination-extravaganza…) It also doesn’t hurt to add inductors/ferrite beads along the power rails (make sure the inductors/ferrites stay in their respective rail, or they’ll start to stink up your lab).

Decoupling capacitors:

Placing decoupling capacitors (100nf/0.1uf) at connections between ground or power and the Daisy board is a common technique to reduce noise. These capacitors act as local energy reservoirs, providing instantaneous energy to the circuit during sudden changes in current demand. They help stabilize the power supply by preventing voltage drops or spikes, which can introduce noise into the system. Decoupling capacitors also act as low-pass filters, attenuating high-frequency noise and ensuring a clean power supply for the circuit.

Inductors or ferrite beads:

Using inductors or ferrite beads along the power rails further enhances noise reduction. These components work as low-pass filters, impeding the flow of high-frequency noise while allowing the desired power supply to pass through. Inductors and ferrite beads have high impedance to high-frequency signals, effectively filtering out noise. Placing them correctly on their respective rails ensures they effectively filter noise without introducing interference.

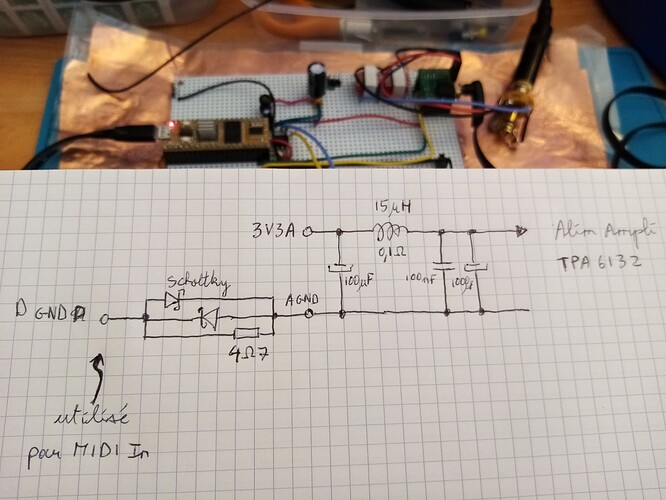

Finally, to remove that “mosquito-somewhere-in-the-room” noise–

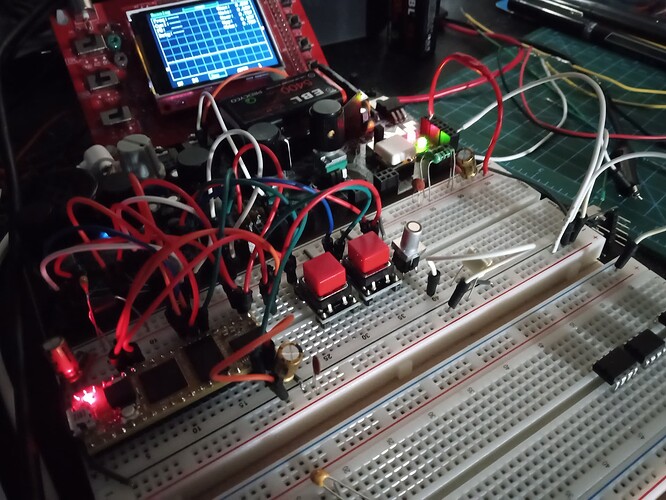

–replaced the breadboard dunlop wires from the power supply to the breadboard with real wires with solder on each end:

Now, there seems to be no audible noise difference between everything off, and everything on, which is ideal!

Also, do not forget to disconnect breadboard power to Vin before connecting the USB for a new code upload!

I hope this helps anyone, especially those just breadboarding and learning–who may run into trouble with the  noise, and that they may not have to scour the net for many possible solutions for noise reduction while breadboarding.

noise, and that they may not have to scour the net for many possible solutions for noise reduction while breadboarding.

Best