Wanted to share a project I’ve been working on, the Modulo.

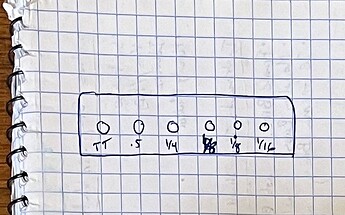

Five or six years ago I had an idea for a tap tempo tremolo pedal with a bunch of momentary footswitches to subdivide the initial tempo into 1/4 , 1/8 , 1/8 triplet, 1/16, and 1/2 notes. I think the idea was to have a pedal with no knobs, just switches, and when one of the footswitches was pressed the effect was engaged and when released the effect would just be bypassed.

Years later I became aware of the Daisy Seed, it seemed like a good way to handle the digital side of the tap tempo circuit and also expand on the effect; having other modulation instead of just tremolo.

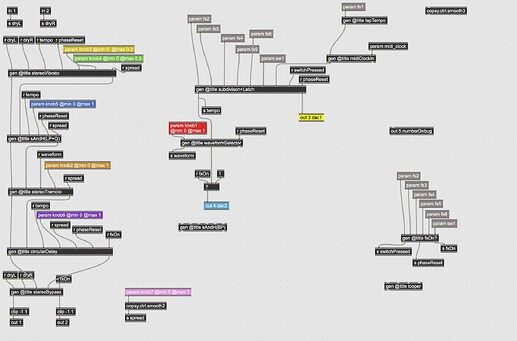

I drafted an early version of the effect on this prototyping platform I built and added controls for tremolo waveform, tremolo depth, vibrato, flanger, and an early version of a sample and hold filter. I added a toggle Latch control to switch the effect from being always in “momentary” mode, to latching onto whichever the last subdivision footswitch that was pressed.

I tried fitting it into a 1032L, but pretty quickly realized that the footswitches being so close together made it not as viable as a foot pedal. As an aside; cramped footswitches on guitar pedals drive me insane. I also wanted the effect to have some stereo capability so added a stereo bypass switch, further cramping the interface. Also getting a little sketchy having a stompswitch so close to the knobs…

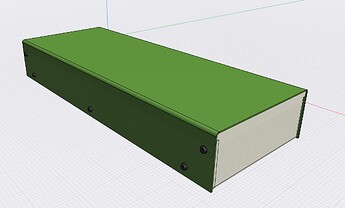

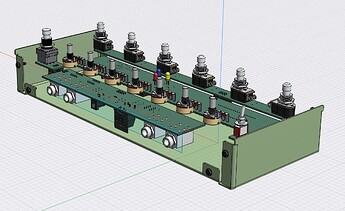

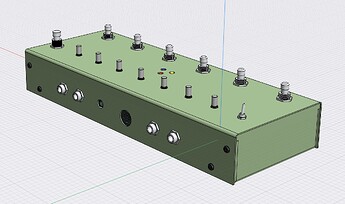

Needing a bigger enclosure I started ooking at the Hammond 1444-18, really more of an amp chassis, but for proof of concept I took the CAD file from the Hammond site, designed all new PCBs in KiCad, and made this mockup. With the new design I added a handful of other features; MIDI Clock in (overrides user tapped tempo), relay based stereo bypass switching, a delay effect, a Spread knob (which spreads the modulation across the stereo field), Bypass/Master Tempo/Active Tempo LEDs.

I was stoked. Looked good, sounded good. And then my hard drive failed and I lost EVERYTHING. My last backup was from a year and a half before. Not a good feeling. I pretty much completely lost motivation for the project (and the other projects I was working on at the time) and took a bunch of time off.

Eventually I got over it and wanted to see this through. The last PCBs I had ordered were still cached on the manufacturer’s site, so was able to download the gerber files and re-trace the boards, rebuilding the KiCad project at the same time. Not a lot of fun and I don’t recommend doing it.

The program for this had all been written in gen~ and there was truly no backup for that, so I re-wrote the whole thing from scratch.

I also started to realize that the enclosure I had chosen wasn’t going to hold up to being stomped on, it’s only 18 gauge folded aluminum, so I decided on a folded steel enclosure.

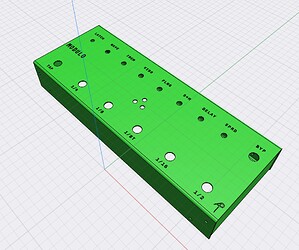

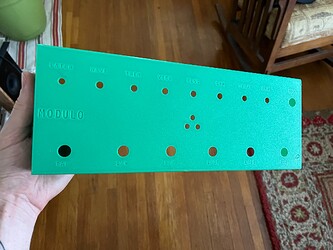

Set this one up the same as the Hammond enclosure, prepped it for 3d printing as a proof of concept, and added preliminary graphics.

And it turned out pretty nice! The boards I had cloned from the old project worked, miraculously.

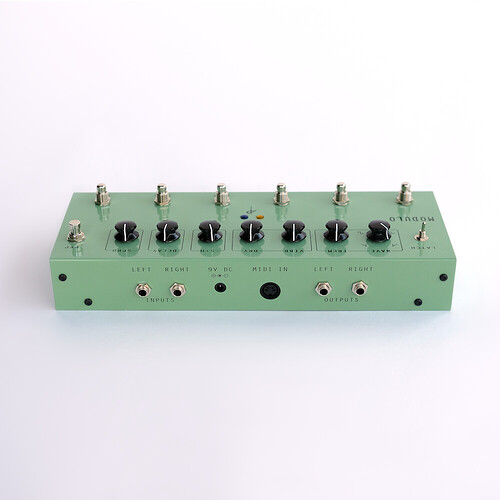

Currently waiting for some samples of the folded sheet metal enclosure and sourcing powder coat / printers. Hoping to make a batch of these available by the beginning of next year.

Thanks for reading! Here are some renders for what (I hope!) the final product looks like.