Hi folks. While using the Daisy Seed Eagle footprint I noticed that the drill holes for the headers are not aligned; they are staggered instead. I assume this is the same idea as: https://www.sparkfun.com/tutorials/114. I think I’ve also seen this called a “locking” design.

I’m using the library from https://daisy.nyc3.cdn.digitaloceanspaces.com/libraries/Electrosmith_Boards.zip with Autodesk Eagle 9.6.2.

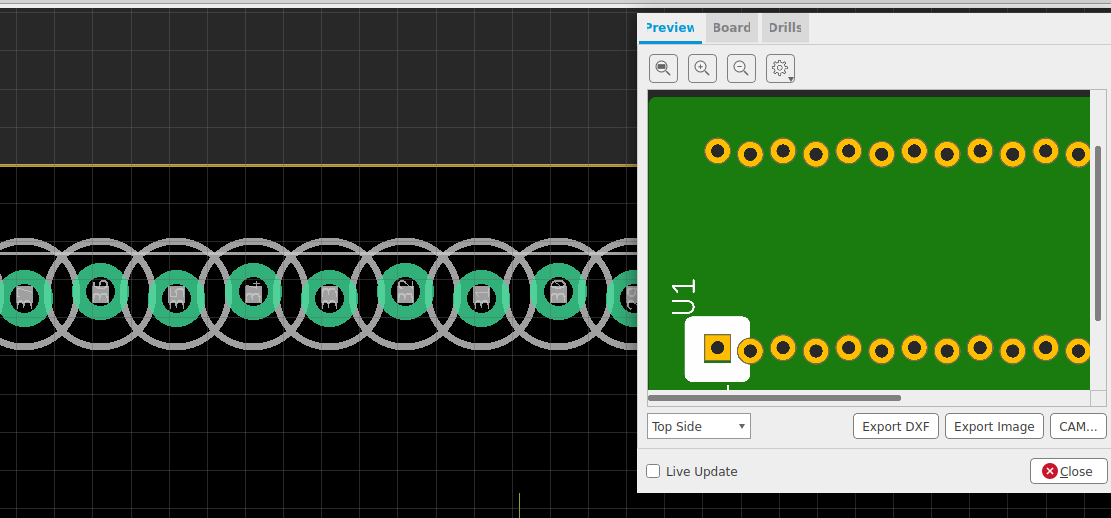

A screen cap in Eagle board designer and the Manufacturing view:

In theory, this all seems fine, but I’ve never used it in practice. It feels like a solution in search of a problem to me, as I’ve never had trouble soldering headers in place. ![]()

Has anyone here had any issues (other than a curmudgeonly obsession with aligned drill holes) using the Eagle footprints provided by Electrosmith? Just curious as I’m about to send some designs for fabrication.

Cheers in advance!